When factory owners look at a quotation for a screw air compressor, the bottom-line price is often the first thing they see. However, experienced engineers know that the purchase price is only the tip of the iceberg. Over a 10-year lifecycle, energy costs account for approximately 80% of the total expenditure, while the initial purchase represents less than 15%.

To help you stop burning money on electricity and maintenance, ZIQI has standardized a configuration that the industry refers to as the "Golden Combination." Let’s dismantle the machine and look at the two components that matter most: the Air End and the Motor.

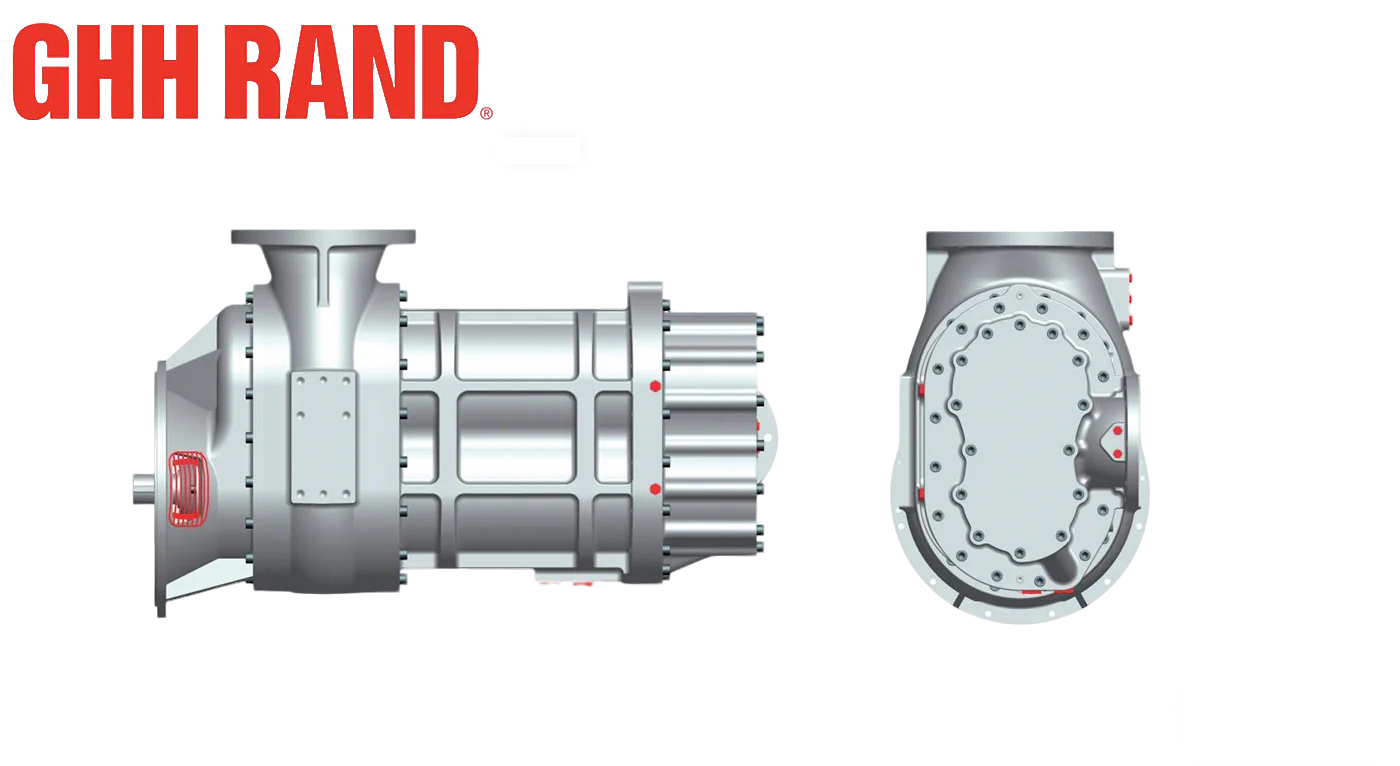

The air end is where the magic happens—where atmospheric air is compressed into power. ZIQI refuses to compromise with domestic copycat brands. We utilize the original German GHH Air End, a component synonymous with precision engineering.

Figure 1: The GHH Air End features a superior 5:6 asymmetric tooth profile for maximum efficiency.

While standard compressors use an older 4:5 tooth profile, GHH utilizes a 5:6 asymmetric profile. This engineering choice is not just for show; it delivers tangible physical benefits:

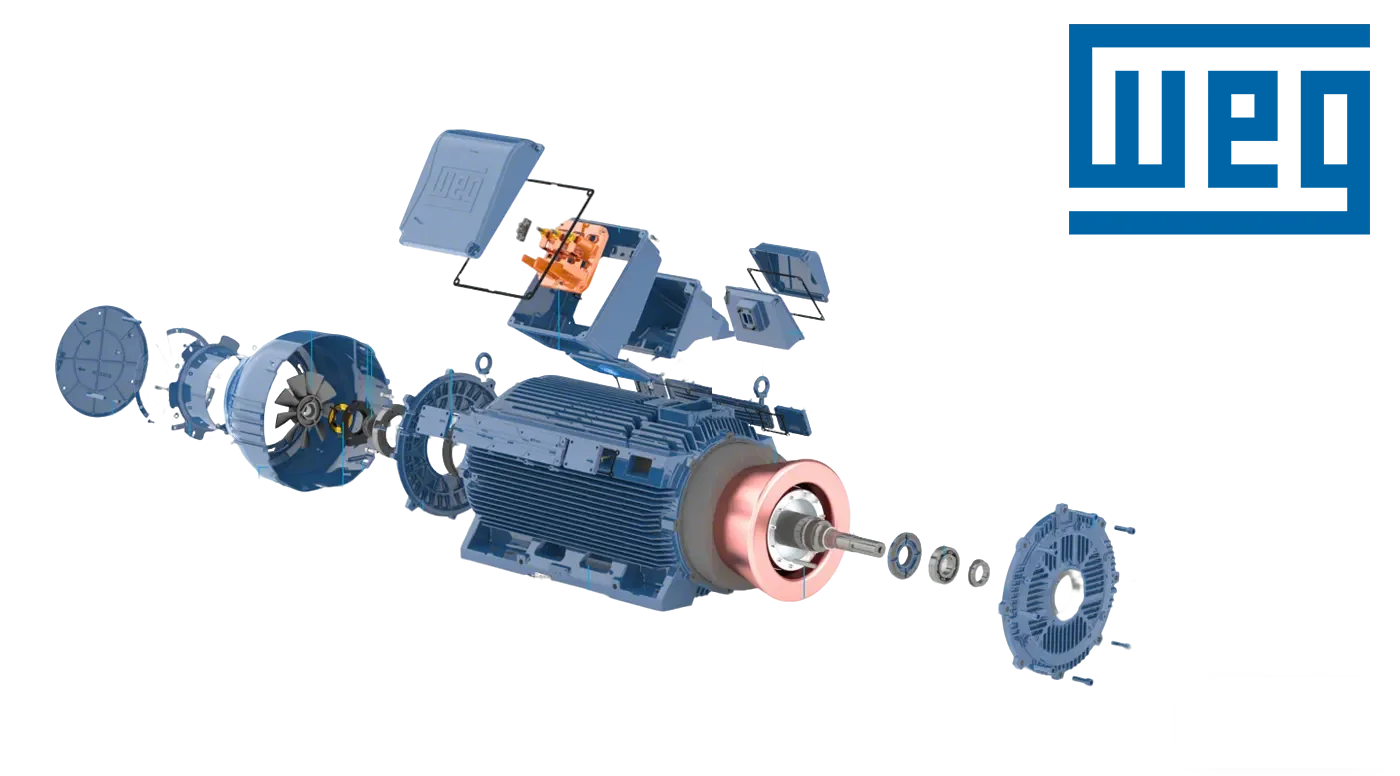

A high-performance air end needs a reliable driver. In an era where energy conservation is paramount, standard IE2 or IE3 motors are no longer sufficient. ZIQI equips its flagship models with WEG IE4 Super Premium Efficiency Motors from Brazil.

Figure 2: WEG IE4 Motors provide robust IP55 protection and significant energy savings.

Upgrading from a standard IE3 motor to a WEG IE4 motor might seem like a small detail on a spec sheet, but the financial impact is massive.

The Reality of ROI: The reduced thermal losses in an IE4 motor mean you save electricity every single minute the machine runs. For a standard 75kW compressor running 24/7, the electricity savings alone can often pay for the price difference of the premium motor within the first 12 months.

Factories are rarely clean, temperature-controlled environments. WEG motors are built to survive:

The market is flooded with low-cost "assembly line" compressors that look identical on the outside but use inferior internal components. These machines are "time bombs" of rising energy bills and potential downtime.

At ZIQI, our strategy is simple: German Precision (GHH) + Global Efficiency (WEG). This configuration ensures that your production line has a stable, continuous, and cost-effective air supply.

Ready to upgrade your facility's efficiency?

Contact ZIQI's engineering team today for a customized energy-saving proposal and detailed technical specifications.